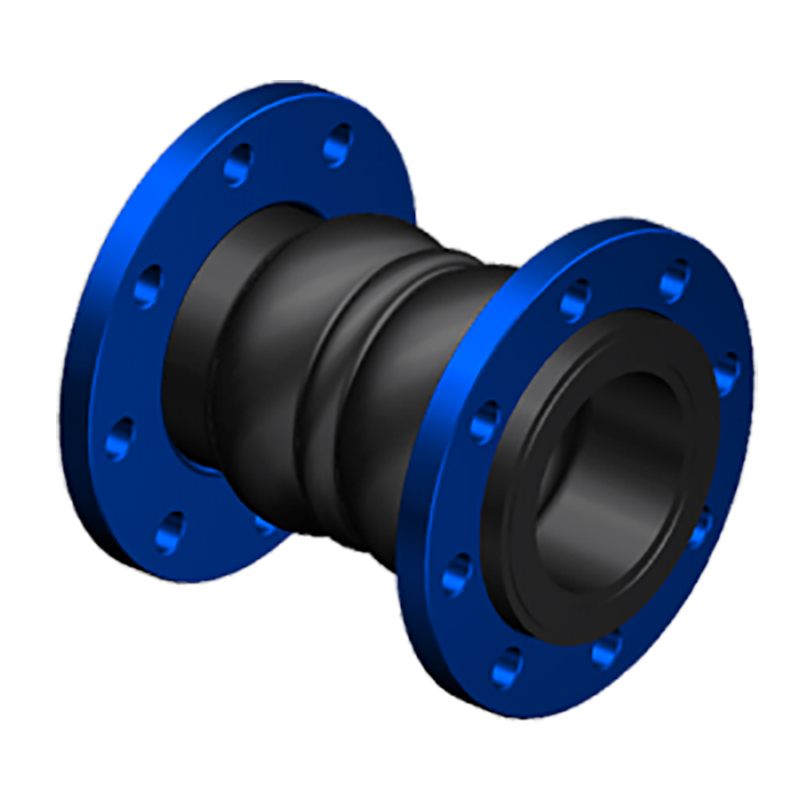

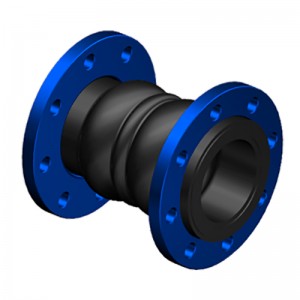

China Gold Supplier for China Single Sphere/Arch Rubber Expansion Joint (GJQ(X)-DF)

Our commission is to serve our users and clients with best quality and competitive portable digital products for China Gold Supplier for China Single Sphere/Arch Rubber Expansion Joint (GJQ(X)-DF), Create Values,Serving Customer!” would be the purpose we pursue. We sincerely hope that all clients will build long-lasting and mutually effective cooperation with us.In the event you wish to get extra facts about our enterprise, Be sure to get in touch with with us now.

Our commission is to serve our users and clients with best quality and competitive portable digital products for China Rubber Expasion Joint, Expansion Joint, Now we have been sincerely consider to grant brand agent in different areas and our agents’ maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We’ve been ready to share win-win corporation.

Details

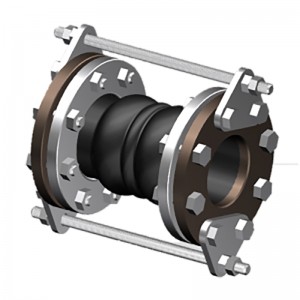

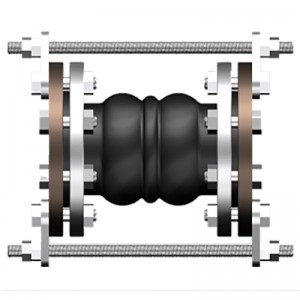

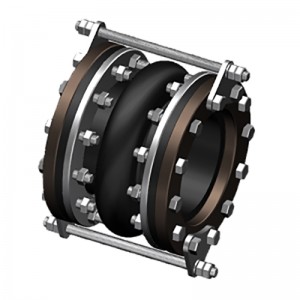

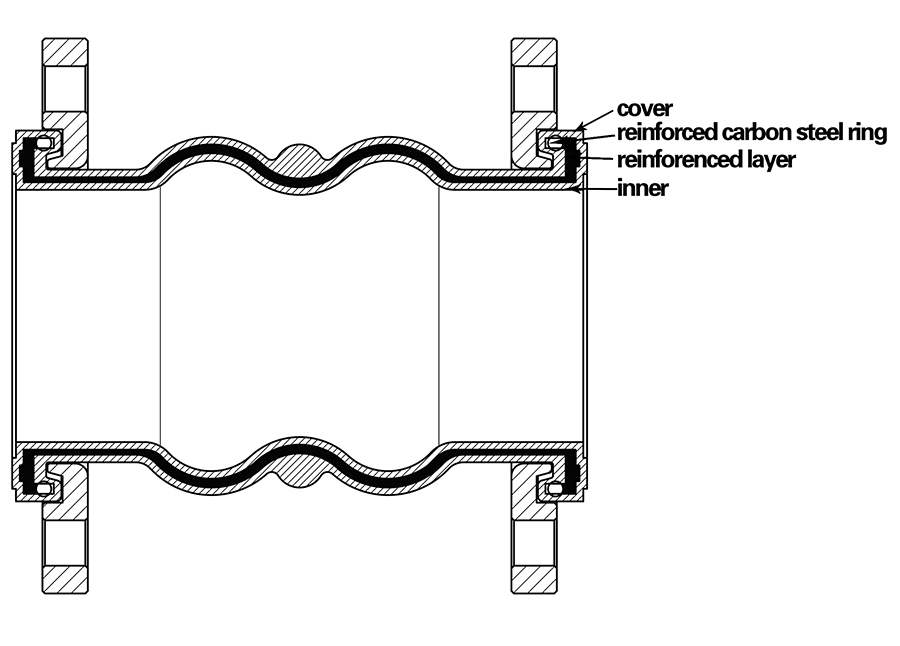

Double-arch products are used where more movement is needed. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Double Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum in. of Hg(mm hg) |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

1 1/2″ |

40 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

2″ |

50 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

2 1/2″ |

65 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

3″ |

80 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

4″ |

100 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

5″ |

125 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

6″ |

150 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

8″ |

200 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

10″ |

250 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

12″ |

300 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

14″ |

350 |

350 |

60 |

35 |

35 |

15° |

10(150) |

26(660) |

|

16″ |

400 |

350 |

60 |

35 |

35 |

15° |

7(100) |

26(660) |

|

18″ |

450 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

20″ |

500 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

24″ |

600 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

Double Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

1″ |

25 |

5″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

1 1/4″ |

32 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

1 1/2″ |

40 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

2″ |

50 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

2 1/2″ |

65 |

7″ |

2″ |

1.188″ |

±1.75″ |

43° |

225 |

26 |

|

3″ |

80 |

7″ |

2″ |

1.188″ |

±1.75″ |

38° |

225 |

26 |

|

4″ |

100 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

34° |

225 |

26 |

|

5″ |

125 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

29° |

225 |

26 |

|

6″ |

150 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

25° |

225 |

26 |

|

8″ |

200 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

19° |

225 |

26 |

|

10″ |

250 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

15° |

225 |

26 |

|

12″ |

300 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

13° |

225 |

26 |

|

14″ |

350 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

9° |

150 |

26 |

|

16″ |

400 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

8° |

150 |

26 |

|

18″ |

450 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

7° |

150 |

26 |

|

20″ |

500 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

7° |

150 |

26 |

|

24″ |

600 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

5° |

150 |

26 |

|

Double Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum in. of Hg(mm hg) |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4 |

32 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

1 1/2 |

40 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

2 |

50 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

21/2 |

65 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

3 |

80 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

4 |

100 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

5 |

125 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

6 |

150 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

8 |

200 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

|

10 |

250 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

|

12 |

300 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang